A Drying Rack in Schedule 1 is necessary to improve the quality of your organic products. Each of these indoor fixtures costs $250 and is an integral part of your production line.

You can place products manually onto the racks, but true rack automation demands proper personnel assignment and workspace organization.

Drying Rack Automation In Schedule 1

Drying-rack automation in Schedule 1 involves a number of essential steps:

- Hire a Botanist: A botanist manages every plant-related task, including drying rack operations. It will be a $1,000 investment for an initial hire plus $200 for a daily salary- a good expenditure, if we may say so, for all the gains down the line.

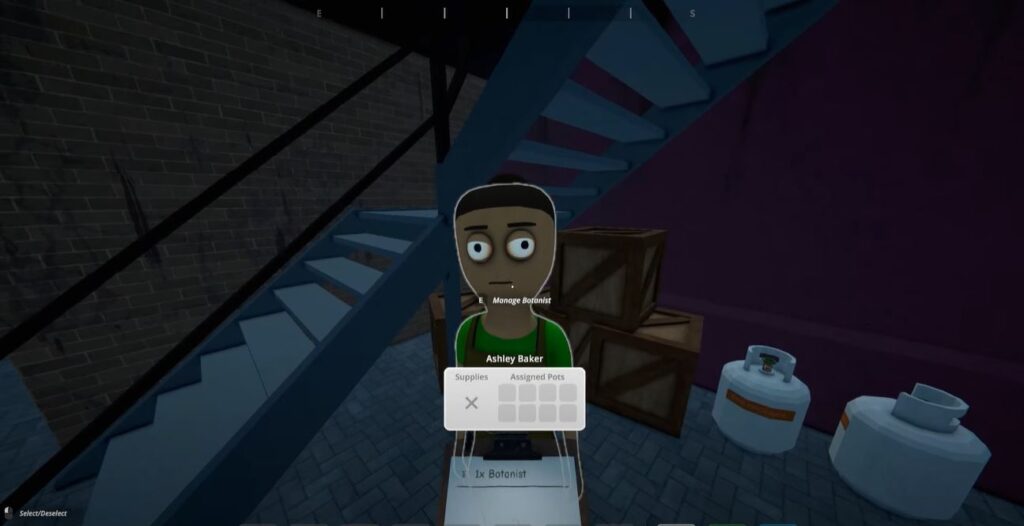

- Assign the Botanist: Use the Management Clipboard to assign your botanist to the drying racks. This assignment is crucial since it is to be accepted by botanists in the context of their workstation.

- Manage Workload Distribution: This will prevent your staff from experiencing overload with work and instead maintain the ratio of 1 botanist per 4 drying racks. This will work against bottlenecks in your production.

- Clear Pathways: Ensure unobstructed access around your drying racks to prevent AI pathing issues that can halt production.

- Connect Storage Systems: Connect appropriate storage facilities to your drying stations to create a seamless workflow from harvesting to drying.

Troubleshooting Drying Rack Automation Issues In Schedule 1

Keeping everything in order, drying rack automation still has its share of problems. Here are 5 actions on how to fix the most common issues:

When Botanists Are Ignoring Drying Racks

If your botanist is in the dry racks standing idle, check for these potential causes:

- Incomplete Assignment: Does the rack appear in the workstation assignment list? Just placing the rack will not lead to full automation.

- Workload Overloaded: Your botanist may choose to prioritize tending to grow pots. It may be necessary to revise the workload or hire extra hands.

- Game Time Issues: Game time settings are frozen (that is, often at 4 a.m.), so progress must wait until you get time to sleep.

Fixing Glitched Drying Racks

At times, drying racks suffer from bugs, which could either delete leaves or freeze the botanist. Try these proven methods:

- Clear Surrounding Areas: Clear any objects blocking the way to the rack.

- Cancel Active Processes: Click on the floating icon above the rack with a drying phase to cancel that entire process. This should restore all missing objects.

- Reset Worker AI: If an employee freezes in near proximity to a rack, you may need to reset their AI through the game activities available to you.

- Reload Your Save: Another option is to load a save from earlier, which remedy has successfully solved for prolonged glitches.

Integrating Drying Racks into Your Wider Operation

For maximum efficiency, integrate your drying rack automation with other aspects of your business:

- Position packers by the storage shelves while the botanist plants.

- Maintain adequate supplies of soil, seeds, and fertilizers to prevent production interruptions.

- Last but not least, remember to deposit employees’ daily wages inside their payment suitcases to keep things flowing.